Giải pháp CBFI® IQF cho thực phẩm gia cầm (1)

Our customized services ensure tailored solutions to meet your specific needs, guaranteeing optimal performance and efficiency.

How Does IQF Freezer Work?

IQF is the abbreviation of "Individual Quick Freezing". In a very short period, the temperature of the food is lowered to a certain temperature below its freezing point.

The moisture inside forms tiny ice crystals, inhibiting Microorganisms' survival, delay food deterioration,

and maintain the original structure and flavor of food after thawing.

Therefore, in the food industry, IQF technology can retain the original flavor and appearance of

food to the greatest extent and meet consumers' needs for food safety and original flavor.

Fresh

Frozen

After cooked

CBFI® IQF Solution for Poultry Foods

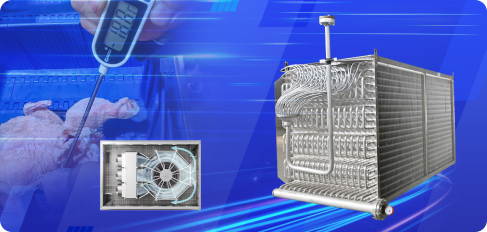

Excellcent Freezing Result

The high-efficiency refrigeration system developed by CBFI®, combined with the unique air duct design, allows the cold air to fully contact the food, so that the food temperature drops to -2~-10 degrees Celsius within 30 minutes, avoiding the formation of large ice crystals, which preserve the product's Taste and nutrition, maintain good presentation. At the same time, it reduces the dry consumption of the product and prevents the formation of snow in the freezer, resulting in an excellent quick-freezing effect, thereby maintaining the natural appearance of the food, increasing food profits, and enabling the food to be stored and transported over long distances for a long time.

Stability

CBFI® spiral quick freezer has the advantage of stability, which ensures the long-term stable operation of the spiral quick freezer and reduces downtime, thereby increasing the profit margin of the quick freezing production line.

1、20 years of experience in refrigeration equipment, and high reliability of refrigeration equipment.

2、The thermal insulation system composed of polyurethane thermal insulation panels ensures the stable and reliable thermal insulation effect of the spiral quick freezer.

3、The use of unique horseshoe-shaped components on the edge of the mesh belt makes the opening and gathering of the spiral mesh belt smoother during operation.

4、The spiral quick freezing machine can be connected to the automated production line, so manual intervention is not required for quick freezing of food.

Food-Grade Safety

CBFI® attaches great importance to food safety. The mesh belt and other parts that are in direct contact with it are made of 304 food-grade stainless steel to ensure the safety of poultry food production.

Energy Saving

Since 2004, CBFI® has been focusing on the manufacturing research and development of refrigeration systems and has obtained more than 60 patents. Using the overlay system, our refrigeration equipment can save 5~8%, so our quick freezer has significant energy-saving benefits in refrigeration.

Customized Services

Our technical support team with more than 20 years of experience will customize a suitable spiral quick freezer solution for you based on your

product quick freezing requirements, packaging form, and site characteristics to optimize the cost of your production line. Contact us today.

Successful Cases

Tajikistan, chicken slaughterhouse

Capacity : 3 Ton / Hour

Yunfu, China, chicken meat processing plant

Capacity:1 Ton / Hour

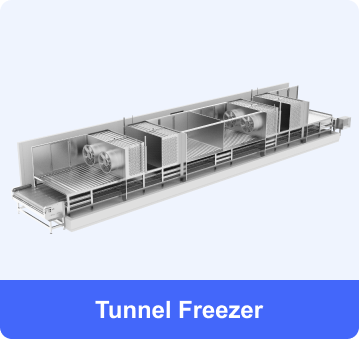

Equipment Suited for Poultry Foods

About CBFI®

CBFI® (Guangzhou Icesource Co., Ltd) is a globally recognized expert in the ice-making and quick-freezing cold storage industry.

With over two decades of dedication, we provide reliable ice-making and freezing solutions to food production enterprises worldwide.

Our commitment is reflected in our brand promise "Customer Benefit from Icesource," ensuring our clients gain the most value from our offerings.

We invest more than 2% of our yearly profits into R&D for energy conservation, in line with our pursuit of innovation.

CBFI® consistently works on developing smart, energy-efficient, eco-friendly, and low-carbon refrigeration equipment.

We aim to elevate CBFI® as a leading industry brand, thus enhancing lifestyles with superior cooling technology.